Page Header - Default

Lorem ipsum dolor sit amet, consectetur adipiscing elit.

Almost Full-Width Heading with Text below

Almost Full-Width Heading with Text below

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Suspendisse pellentesque tristique purus, ac pretium quam accumsan in. Fusce feugiat eros id metus sollicitudin varius. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Quisque placerat luctus leo ac tincidunt. Vestibulum ut ipsum eget lacus tempor ultrices. Duis nisi augue, laoreet quis orci vel, facilisis tristique augue. Nunc laoreet pellentesque nunc, sit amet sagittis libero sodales sed.

Sed congue velit sed metus consequat, fermentum facilisis lacus pellentesque. Duis imperdiet auctor quam, ullamcor.

Alternating Content and Image Columns

Alternating Content and Image Columns

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Suspendisse pellentesque tristique purus, ac pretium quam accumsan in. Fusce feugiat eros id metus sollicitudin varius.

Lorem ipsum dolor sit amet, consectetur adipiscing elit.

Alternating Content and Image Columns

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Quisque placerat luctus leo ac tincidunt. Vestibulum ut ipsum eget lacus tempor ultrices. Duis nisi augue, laoreet quis orci vel, facilisis tristique augue. Nunc laoreet pellentesque nunc, sit amet sagittis libero sodales sed. Sed congue velit sed metus consequat, fermentum facilisis lacus pellentesque. Duis imperdiet auctor quam, ullamcor

Lorem ipsum dolor sit amet, consectetur adipiscing elit.

timeline of events

wright’s progression to perfecting performance.

1927

Our Founder - C. Nelson Wright

From selling tools out of the back of his car to establishing our Barberton-based company.

A one-time tool salesman, Mr. Wright established our Barberton, Ohio-based company in 1927. Under his direction, Wright expanded to become a nationally and internationally known manufacturer with distribution to hardware, automotive and industrial markets.

1940

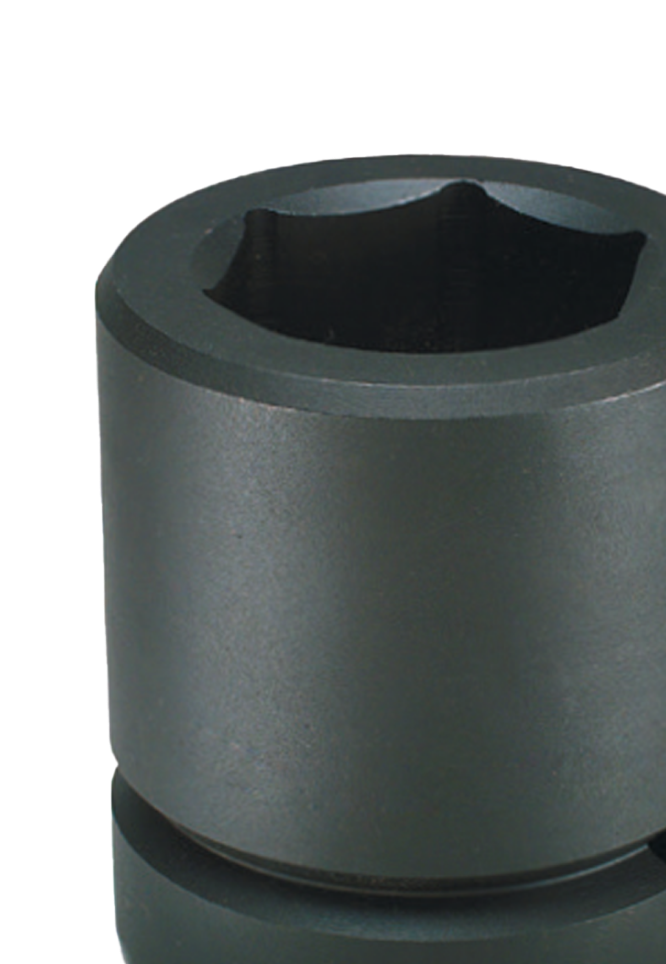

Hot Forging Sockets

Higher toughness, longer wear and better reliability.

Barberton, Ohio begins production on hot forging sockets in their plant. By going to a hot forge process, it keeps materials from strain hardening at high temperature, which results in optimum yield strength, low hardness and high ductility.

1967

Our Innovator - Richard “Dick” Wright

“Always remember, we are not here for our satisfaction, we’re here to serve the customer. That must come first, if we serve the customer well, we will be served.”

Following in his father's large footsteps in 1952, Dick spent his entire career at Wright. Starting as an engineer, he eventually was promoted to Chief Engineer, then Purchasing Agent and later becoming Vice President. Finally, in 1967 he was able to fill his father's shoes and became President. For almost four decades and into the new millennium Dick led Wright. In January 2007, he retired from his position yet still remained Chairman of the Board until 2012.

1974

Wright Improvment Teams

"We have been a company that has constantly put our customer on the forefront of our minds and our innovations. We continually ask ourselves how we can make our products better, the experience better, and our processes better for you, our customers.”

Since 1968, Terry Taylor has promoted employee participation and engagement which led to the activation of our internal quality program, W.I.T. While in this program, employees pledge to do their part to provide our customers with the highest quality products and best service.

1987

Wright Drive®

More strength. More torque. More tool-to-fastener contact.

The Wright Drive® was created and patented by the Wright Tool Company taking full advantage of advanced CAD/CAM technologies.

1998

New Ownership

Rooted in Barberton OH, USA and privately-held.

Terry and Patricia Taylor and Tom Futey become new owners of the Wright Tool Company continuing to be a management-owned, privately-held company in Barberton, Ohio since 1927.

2002

Wright Grip®

More torque. Longer life. Higher strength.

Wright Grip is a design evolution for open-end wrenches similar to what the Wright Drive® was for sockets and box wrenches. The design utilizes advanced CAD/CAM technologies to improve the wrench-to-fastener contact areas.

2007

Our Culture - Pat Taylor

Perfecting Performance is written in Pat’s own signature and the mission of our company.

Perfecting Performance is a culture that Pat established her entire career, and it continues on into our future. She was a trailblazer before there were trails and to this day, her words to each new employee still ring true throughout our factory and offices, “don’t let me down.”

2021

New President

“Our vision has always been to ensure confidence and protect those that are building our tomorrow. When we do that, we’re forging more than just tools. We’re forging partnerships. We’re forging respect. Something we don’t intend to lose any time soon."

On February 22, Tom Futey was named by the Board of Directors to President of the Wright Tool Company. In the company’s nearly 100-year history, Tom is only Wright's 4th President.

Center Column Overlay w/ Image - Text

Center Column Overlay w/ Text - Image

Content w/ Newsletter Signup

Content w/ Newsletter Signup

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Quisque placerat luctus leo ac tincidunt. Vestibulum ut ipsum eget lacus tempor ultrices. Duis nisi augue, laoreet quis orci vel, facilisis tristique augue. Nunc laoreet pellentesque nunc, sit amet sagittis libero sodales sed. Sed congue velit sed metus consequat, fermentum facilisis lacus pellentesque. Duis imperdiet auctor quam, ullamcor

Lorem ipsum dolor sit amet, consectetur adipiscing elit.

Events Slider

Events Slider

Small Firms Can Win Big

Advantages of smaller, privately held companies versus large, public companies.

exploreSafety Tips for Hydraulic Torque Wrenches

Seven safety tips to consider when handling hydraulic torque wrenches.

exploreChoosing The Proper Drive Size

Proper drive size selection combined with proper usage will ensure that you can safely and effectively complete a variety of tasks.

exploreSelecting the Right Wrench for the Job

Wrenches are a common hand tool to tighten or loosen nuts and bolts. Learn more on wrench openings and selecting the right wrench for the job.

exploreSafety Based Wrench Selection

Present practice in selecting wrenches is based on experience of what works and what doesn’t. In this blog post, we discuss safety based wrench selection

exploreWrench Q&A Part One

For almost 100 years, Wright has been forging tools and has a commitment to professional grade tools. With being experts in the field, we decided to answer some of the top questions our customers have when it comes to wrenches.

exploreWhy Use Spline Wrenches and Fasteners

There is no such thing as a strength of a wrench by itself. Its strength depends on the type and strength of the fastener on which it is used and the clearance between the wrench on the fastener. No more torque will be transmitted than the strength of its weakest member, be it the wrench or the fastener. It is much better if the wrench is stronger than the fastener.

exploreWrench Q&A Part Two

In this two-part series we answer some of the top questions our customers have when it comes to wrenches.

exploreHow to Save Money, Time, and Weight with Better Fasteners and Wrenches

As a tradesman, it’s important to understand how you can save money and time. By realizing small improvements you can make, you can enhance your profitability. In this blog post, we provide you knowledge on how better fasteners and wrenches can help.

exploreWhy Wrench Problems Happen and What Can be Done About It

Not all wrench breakage should be blamed on users. Fasteners have gotten stronger and are being tightened to higher torques. In addition, they are being turned with wrenches designed and built before today’s stronger fasteners were developed.

exploreTips for Removing 12-Point Fasteners

For the professional who services equipment and has trouble removing 12-point fasteners, there are a few things that can be done to help make it easier.

exploreQuick Way to Get the Correct Size Wrench

It’s common knowledge that if you try too small of a wrench on a fastener, it won’t fit, and you’ll lose time changing wrenches

exploreNew Twist on Wrenches

We cannot do without fasteners to hold things together and fasteners must be turned with wrenches. Wrenches do not appear to have changed much in 50 years, but fasteners certainly have. Most fasteners used to be made with steel with an ultimate strength of 60,000 psi.

exploreHow Strong is My Wrench

Tools are very carefully designed and inspected to be in accordance with the American Society Mechanical Engineers (ASME) standards, which provide values for strength as well as dimensions. In practice, our designs pack as much strength as we can into the allowable space. This means that we are often substantially stronger than the value in the standard.

exploreHow to Avoid Wrenching Problems

The difference between the wrench breaking and not breaking may be just a few percentage points in strength, so the factors discussed here might sound minor, but they can produce very substantial results in time, money, and safety.

exploreForged to Finish

At Wright Tool, we take immense pride in our commitment to forging the highest quality tools right here in the USA, all under one roof in Barberton, Ohio.

exploreBuilding Tomorrow with USA-Made Tools – Wright’s Vision for Quality and Innovation

At Wright Tool, we believe that manufacturing tools domestically is not just a choice but a commitment to superior quality. Here’s a closer look at why American-made tools, like those we produce in Barberton, Ohio, are more important now than ever before.

exploreExploring Wright’s Cutting-Edge Innovations

Wright is committed to quality and technological advancement and has developed three groundbreaking patents: Wright Grip 2.0®, Wright Drive 2.0® and Wright Square.

exploreCase Study Summary: Gogel Fastener and Wright Partnership

Gogel Fastener and Wright, two established Ohio companies, have enjoyed a strong partnership for over 20 years but recently experienced exponential growth when they partnered on an apprenticeship tool kit program funded by a government grant.

exploreCase Study Summary: Midland Tool & Supply and Wright Partnership

Midland Tool & Supply, based in Oak Park, Michigan, strengthened its partnership with NetPlus Alliance preferred supplier Wright in 2020, to take advantage of the shared values of quality U.S.-made products, timely delivery, strong brand marketing and personal relationships.

exploreBreadth of Depth

When it comes to high-quality hand tools, Wright stands out as a trusted name in the industry. For almost 100 years, Wright has been innovating, engineering and forging tools that exceed where others fail.

exploreNearly a Century of Innovation and Craftsmanship

Since 1927, Wright has been forging respect—all the way from the founders to our current production team. At Wright, we never settle for second-rate. We keep the wheels in motion to make sure each hot-forged steel tool won’t crack under pressure.

exploreBeyond the Basics: The Power of Wright’s Striking Wrenches

Wright striking wrenches feature the patented Wright Drive 2.0 design, which distributes contact stress more effectively than any other wrench.

exploreBuilt to Last: Celebrating the People and Commitment That Define Wright

At Wright, our story isn’t just about the tools we make, it’s about the hands from each of our 17 departments that touch every wrench and socket we produce.

exploreHonoring DeJohn Sales’ Legacy of Partnership and Service

For over five decades, DeJohn Sales has been a trusted force in the industry — representing quality, integrity and commitment to their customers. As they celebrate this remarkable 55-year milestone, we at Wright are proud to reflect on the partnership we've shared and the impact they’ve made on our mutual success.

exploreEverything You Need to Know About Black Oxide

Today, we’re breaking down what black oxide really is, how and why Wright uses it, and what you need to know to properly maintain it. Whether you’re working in heavy industry or just want your tools to last, understanding black oxide is key to keeping performance high and corrosion low. Let’s get started.

exploreWright Featured on the Manufacturing Report Podcast

Wright recently took the spotlight on the Manufacturing Report podcast, where president and co-owner Tom Futey shared insights into the company’s nearly 100-year commitment to American manufacturing, tool innovation and skilled workforce development.

exploreBuilt with Purpose: The Craftsmanship Behind Every Wright Tool

From the very conception to the final inspection, each Wright tool carries the mark of American-made quality, forged through generations of experience and an unwavering commitment to getting it right.

exploreFrom Factory Floor to Walk of Fame: Honoring Wright Chairman Terry Taylor

Recently, the City of Barberton honored one of its own in a truly special way. Terry Taylor, chairman of Wright, was officially inducted into the 2025 Barberton Walk of Fame, a recognition reserved for individuals whose service, leadership and dedication have left a lasting mark on the community.

exploreHow Customer Input Sparked the Creation of Wright Tool’s Railroad Ratchet

Great product ideas often come from the people who use tools every day. The Wright railroad ratchet is one of those examples, a tool born directly from a customer’s challenge and refined through engineering expertise.

exploreWhat is a Quality Wrench

A quality wrench isn’t defined by a single feature. It’s the result of hundreds of decisions from material selection, engineering and people who care deeply about doing things the right way.

exploreFeatured Animated Text

Featured Testimonial

Featured Testimonial

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Quisque placerat luctus leo ac tincidunt. Vestibulum ut ipsum eget lacus tempor ultrices. Duis nisi augue, laoreet quis orci vel, facilisis tristique augue. Nunc laoreet pellentesque nunc, sit amet sagittis libero sodales sed. Sed congue velit sed metus consequat, fermentum facilisis lacus pellentesque. Duis imperdiet auctor quam, ullamcor

Lorem ipsum

Heading w/ Image Left and Content Right

Heading w/ Image Left and Content Right

Lorem ipsum dolor sit amet, consectetur adipiscing elit.

Lorem ipsum dolor

.jpg)

Innovation Detail Grid

01

Lorem ipsum dolor

02

Lorem ipsum dolor sit amer

03

Lorem ipsum dolor sit amet, consectetur adipiscing elit.

04

Lorem ipsum dolor sit amet, consectetur adipiscing elit.

Innovation Explanation

Innovation Explanation

.jpg)

Lorem ipsum dolor sit amet, consectetur adipiscing elit.

.jpg)

Lorem ipsum dolor sit amet, consectetur adipiscing elit.

Lorem ipsum dolor sit amet, consectetur adipiscing elit.

Lorem ipsum dolor sit amet, consectetur adipiscing elit.

.jpg)

Lorem ipsum dolor sit amet, consectetur adipiscing elit.

.jpg)

Lorem ipsum dolor sit amet, consectetur adipiscing elit.

Joseph says

I use Wright tools on pressure transducers for aerospace testing. I use them because they are made in the USA, and as we know, American tools are the best. The manufacturing philosophy and quality of this company is right on the money, which helped me make my decision to purchase Wright tools. They perform flawlessly. The hand feel of the wrenches is perfect and a product that comfortable to grip gives me the confidence in high pressure (psi) applications.

Owen says

I just want to thank you for being an American company and for making great products. I just found out that you make all your tools in the U.S. out of U.S. steel. I will be buying all my tools from you from now on. This country needs more companies like yours.

Tim says

I work in aviation, mostly on the oxygen systems. There is very little room to work on these systems and even less room for error. I could not ask for a better tool. When my 1/4" ratcheting torque wrench stopped ratcheting, I called Wright's Customer Service and they went above and beyond, as this tool is irreplaceable. I chose the Wright wrench, which is compact, precise, and adjustable. It outperforms the "truck" torque wrenches hands down.

Jeff says

I'm creating a tool room for our locomotive machinists. I learned of Wright tools when I was doing on-site engine over-hauls in the power generation industry. I needed a ¾” drive ratchet that was fine tooth and could break main bearings free that were torqued to 740 ft-lbs. I purchased #6425 instead of the equivalent of another brand. The Wright tool exceeded expectations. I am a certified ASE master diesel technician and a licensed aircraft mechanic, and I have used everything. I'm now a mechanical training manager at a railroad. If there's anything I can do with respect to trying new tools or offering advice for new tools please don't hesitate to ask. I'm a major advocate of keeping Americans working and prefer to see American money supporting American jobs.

Gadalya says

Please allow me the opportunity to give praise where praise is due. A lifelong industry professional, I have been raised with the good, the bad, and the ugly. Your products have been an amazing example of quality, efficiency and ease. Thank you for keeping a company like yours going strong.

Matt says

I love this company! They are the epitome of what a great American tool company should be. Every socket I own is made by Wright, at least half of my ratchets and all of wrenches. In the years I've spent as an automotive and motorcycle mechanic, I've never once been disappointed by my experience with these tools.

Elizabeth says

Amazing place to work for, and just as it says on the website, the tooling made here is of the highest quality. Everyone takes incredible pride in their work and it shows in the final product.

Andrew says

Quality USA made products with good accuracy. Some of the Wright torque wrenches come with calibration certificates and compare favorably to expensive brands. Update: their wrenches and sockets are top notch too (just got the 3xx, 466, 467, 915 and 958 sets).

Text Left w/ Image Right Flush

Text Left w/ Image Right Flush

Lorem ipsum dolor sit amet, consectetur adipiscing elit.

Lorem ipsum dolor sit amet, consectetur adipiscing elit.

Lorem ipsum dolor sit amet, consectetur adipiscing elit.

Text Left w/ Upper Callout, Bottom Link, Image Right

Text Left w/ Upper Callout, Bottom Link, Image Right

Lorem ipsum dolor sit amet, consectetur adipiscing elit.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Quisque placerat luctus leo ac tincidunt. Vestibulum ut ipsum eget lacus tempor ultrices.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Quisque placerat luctus leo ac tincidunt. Vestibulum ut ipsum eget lacus tempor ultrices.

Lorem ipsum dolor sit amet, consectetur adipiscing elit.

Text Right w/ Image Left Flush

Text Right w/ Image Left Flush

Lorem ipsum dolor sit amet, consectetur adipiscing elit.

Lorem ipsum dolor sit amet, consectetur adipiscing elit.

Lorem ipsum dolor sit amet, consectetur adipiscing elit.

WYSIWYG Left - Image Right Flush

WYSIWYG Left - Image Right Flush

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Quisque placerat luctus leo ac tincidunt. Vestibulum ut ipsum eget lacus tempor ultrices. Duis nisi augue, laoreet quis orci vel, facilisis tristique augue. Nunc laoreet pellentesque nunc, sit amet sagittis libero sodales sed. Sed congue velit sed metus consequat, fermentum facilisis lacus pellentesque. Duis imperdiet auctor quam, ullamcor

Section Label

Heading

Content

Callout

Heading 2

Content 2

Callout 2