January 16, 2023

Selecting the Right Wrench for the Job

Wrenches are a common hand tool to tighten or loosen nuts and bolts. The head of the wrench is used to grip onto the nuts and bolts and determines the maximum width across the flats for a corresponding nut and bolt. In this blog post, we will discuss more on wrench openings and selecting the right wrench for the job.

When working with a wrench, you need to ensure that the nut or bolt is deep into the jaws of the wrench. If you don’t have it into the jaws of the wrench, then you won’t have proper contact for removal or tightening. If you are using a wrench with the wrong opening, the wrench will slip off the nut or bolt and could cause damage or injuries to you or others. To avoid damage, always select a wrench jaw size that corresponds to the nut, bolt or fastener you’re working on. Also, make sure your wrench’s jaw is completely in contact before you apply pressure.

Let’s look at some of the most popular wrenches and what they can do to help you on the job.

The flat jaws of the open-end wrench will only make contact with two corners of the nut. Because the head is offset, this allows you to work in tight or restricted spaces.

A box-end wrench has an enclosed head and provides more leverage by completely enclosing the nut. Box-end wrenches are great for loosening stuck fasteners as they apply more torque with less chance of causing damage.

An adjustable wrench provides a better grip to tighten and loosen nuts and bolts. Because of the moveable lower jaw, you’re able to adjust the wrench size for the workpiece.

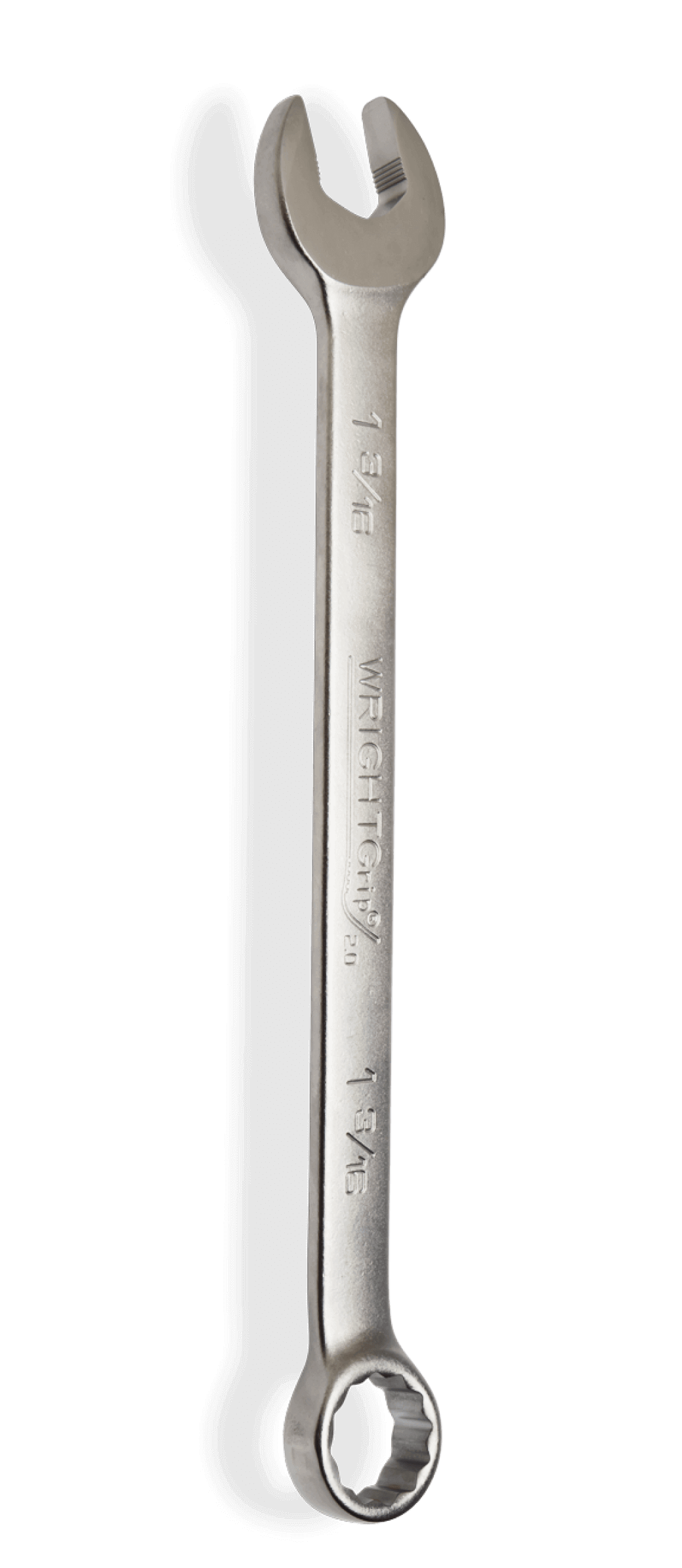

A combination wrench has an open-end and a box-end to help with hard-to-loosen nuts. The box-end can loosen the nut, while the open-end can be used to fully unscrew it.

Socket Wrench

A socket wrench allows you to turn nuts and bolts with more ease with the ratcheting feature. It’s primarily used for tightening or loosening a wide selection of fastener sizes and types.

Now let’s look at the wrenches that are industry focused when it comes to the job.

Striking wrenches are short, thick wrenches with a block shape on the end of the handle. While the wrench is placed on a fastener, the block end is struck by a hammer to provide additional force to help loosen or tighten rusty bolts.

An adjustable spanner wrench is similar to an adjustable wrench as it allows the user to grip onto a fastener to loosen or tighten a nut or bolt. A spanner tool is designed to be more flexible with the moveable jaw and enables the user to tackle multiple fastener sizes. Spanner wrenches are often used to tighten shafts or pipes.

Crowfoot wrenches are ultra-compact, open-end wrenches made to fit into tight spaces where other tools can't reach. These especially come in handy when needing to reach around obstacles.

Flare nut wrenches have an opening in the wrench head that allows a brake line or obstruction to pass through it.

A spud wrench has an adjustable wrench on one end and a tapered spike on the other. The spike is used to help line up bolt holes when installing pipe fittings, doing automotive work or—in the case of iron workers—for lining up bolt holes in girders and beams.

Fracking Wrench

Fracking wrenches are used by crews as they work on blowout preventers and flanges in pipeline construction and maintenance.

Offset striking wrenches help to reach deeply countersunk nuts or bolts that can’t be reached with sockets or standard wrenches.

These wrenches are special-purpose tools designed and intended only for use with heavy-duty fasteners where shock or impact is needed to fully tighten or loosen.

It is important that wrenches provide a close fit. A close fit ensures that they are stronger and do not damage the fastener. Newer designs of wrench openings, such as the Wright Grip 2.0, provide more torque with less fastener damage, distributing stress evenly over a larger contact area and away from the fastener corners.

Each type of wrench can help a user to minimize or maximize the amount of force needed to tighten a smaller or larger nut. Before starting on a job, verify that you’re using the correct wrench for the application and that the wrench opening provides a close fit onto the fastener.

To check out our full line of wrenches visit, https://www.wrighttool.com/products/wrenches