February 2, 2026

What is a Quality Wrench

A quality wrench isn’t defined by a single feature. It’s the result of hundreds of decisions from material selection, engineering and people who care deeply about doing things the right way. At Wright, quality isn’t an accident. It’s designed, forged, tested and verified at every step.

Here’s what truly goes into a quality wrench.

It Starts with the Right Steel

The foundation of any quality wrench is the raw material. Wright uses 100% domestic, high-quality alloy steel, carefully selected for consistency and performance.

Lower-quality steels, often sourced overseas, can contain more impurities. These impurities disrupt grain flow in the steel, increasing the risk of fracture under load.

One Roof, Total Control

One of Wright’s biggest advantages is that nearly everything happens under one roof in Barberton, Ohio.

From:

- Steel inspection

- Forging

- Machining

- Heat treatment

- Finishing

- Final inspection

Each step is tightly controlled, inspected and verified before moving on.

Optimized Heat Treatment for Real-World Use

Heat treatment plays a critical role in wrench performance. ASME standards allow a wide hardness range, but Wright has carefully identified a sweet spot that balances strength with toughness.

By optimizing hardness levels, Wright wrenches are:

- Strong enough to handle high torque

- Tough enough to resist brittleness

- Durable enough for extreme conditions

This balance is especially important in industrial environments, where tool failure can mean serious injury.

Patents and Innovations

A truly quality wrench doesn’t just rely on strong materials and precise manufacturing; it also requires thoughtful engineering that improves how the tool performs in real-world applications. At Wright, innovation is driven by the challenges professionals face every day, especially in high-torque and safety-critical environments.

That commitment to performance and user safety has led to the development of several patented technologies designed to increase grip, reduce fastener damage and deliver more consistent torque. These designs don’t replace the fundamentals of quality; they enhance them.

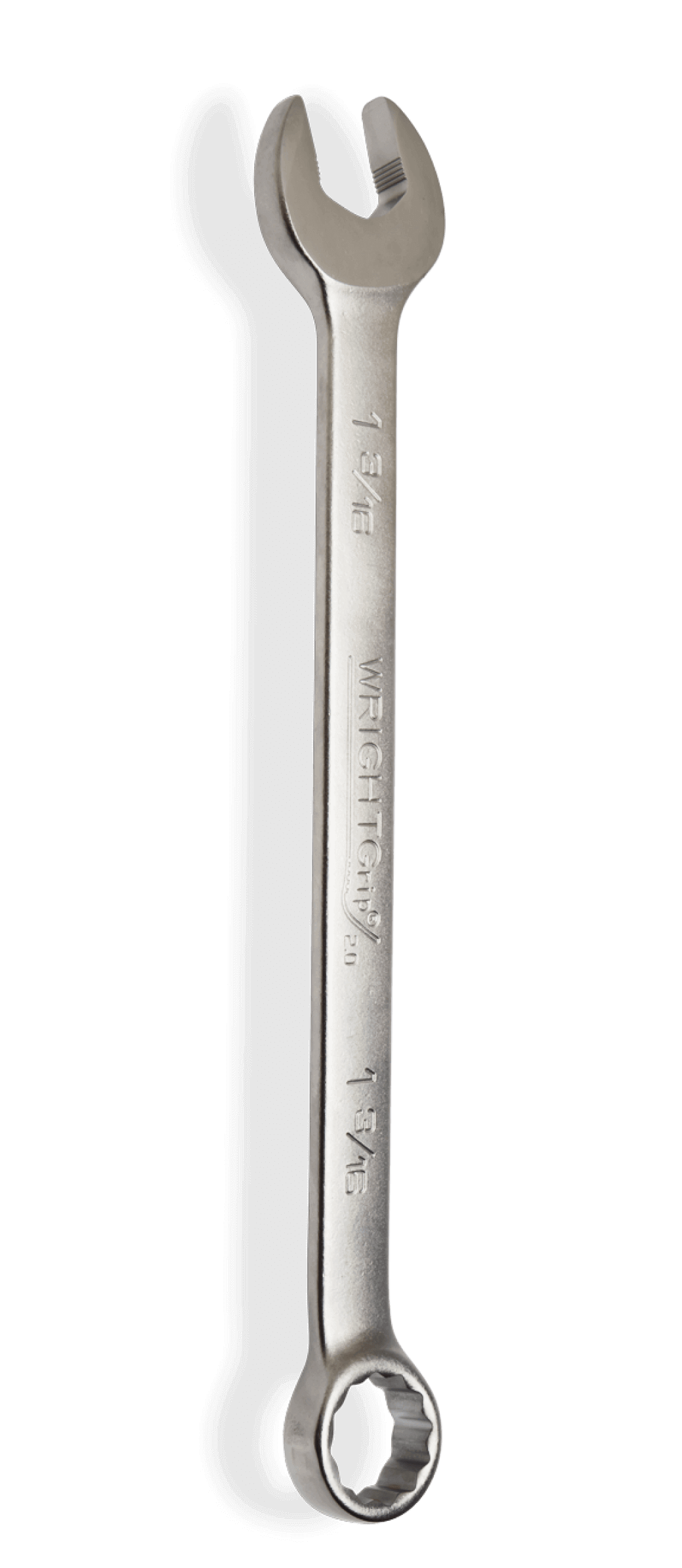

Wright Grip 2.0

Wright Grip 2.0 is engineered to address two common problems: jaw slippage and fastener damage. By increasing steel-to-fastener contact in high-stress areas, the design strengthens the wrench and helps reduce permanent jaw spread over time.

Key benefits of Wright Grip 2.0 include:

Improved torque transfer — Force is distributed across a larger contact area, shifting stress away from fastener corners to reduce rounding and slippage.

Strategic grooves and teeth — Precisely placed features inside the wrench jaws improve engagement and help prevent fasteners from twisting under load.

Durability through precision — Manufactured using premium Wright alloy steel and precision broaching, each wrench size features custom-engineered contact points for consistent fit and performance.

Wright Drive 2.0

Wright Drive 2.0 enhances socket and wrench performance by improving how contact stress is distributed between the tool and the fastener.

Key design advantages include:

Expanded contact area — The Wright Drive 2.0 design delivers significantly more tool-to-fastener contact than traditional designs, improving torque transfer while reducing fastener distortion.

Corner protection — The Wright Drive 2.0 shifts force away from fastener corners, increasing strength and reducing rounding.

Improved grip on worn fasteners — The design provides better engagement on undersized or previously rounded fasteners, helping professionals maintain control in challenging applications.

Quality Is Also About People

Even the best materials and designs mean nothing without skilled people behind them.

Wright’s workforce includes employees with decades of experience who take pride in craftsmanship and accountability. Quality checks happen at every stage, not because they’re required, but because they’re expected.

That culture shows up in the final product.

Built for Professionals, Not Shortcuts

A quality wrench isn’t just about meeting a standard; it’s about exceeding expectations. Wright doesn’t design tools to be “good enough.” They design them to perform in the toughest environments, where failure is not an option.

That level of performance starts with people. Wright’s team brings precision and pride to their work every single day, many of whom have spent decades refining their skills and passing down hard-earned knowledge. This isn’t just manufacturing. It’s a hands-on craft rooted in tradition, driven by purpose and defined by an uncompromising commitment to material integrity, engineering excellence and skilled craftsmanship.