April 29, 2024

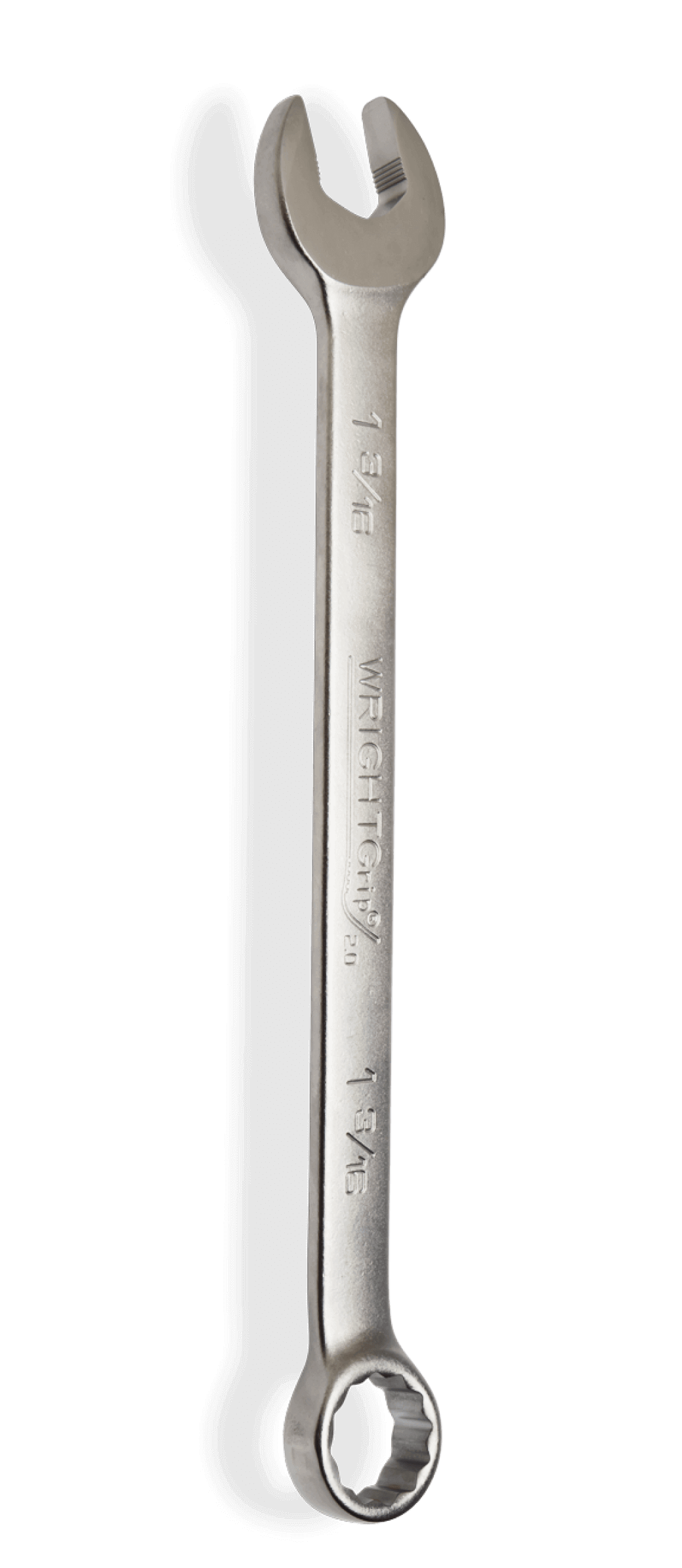

How to Avoid Wrenching Problems

The difference between the wrench breaking and not breaking may be just a few percentage points in strength, so the factors discussed here might sound minor, but they can produce very substantial results in time, money, and safety.

The first step with socket wrenches is to use the largest drive possible. Most sizes of openings are available in three different drives. The largest is obviously the strongest and should be used most of the time. The smallest drive should be used only when there is not space for a stronger wrench.

The next step is to buy high-quality tools. There is a difference both in strength and tool life when comparing tool quality. Saving a small amount on the price of the tools may result in delays or damage that is very much more expensive than the amount saved.

The third step is to get help from a premium tool manufacturer that can provide useful advice. Fourth, if standard tools will not do the job and re-engineering the joint is not possible, special tools can be tailor made for a particular application. A tool manufacturer is in a much better position to both design and build wrenches that fit into problem spaces that are substantially stronger.

Safety

Buying top quality wrenches and replacing worn wrenches is always a good safety measure. However, it is virtually impossible to calculate the load at which a particular wrench will break on a particular fastener. But even if this could be done, there is always the chance that the wrench has been weakened by prior misuse. Therefore, a well-trained user will know there is a possibility that the wrench might break, the fastener might break, or the wrench might slide off the fastener and, therefore, the user braces themselves so they decrease the chance of injury if any one of these situations happen.

While wrenches have gotten somewhat stronger, the maximum strength of wrenches is limited by their size because they must fit in the available space which may have been based on the size of wrenches in the ASME standards or in the catalogs of the various wrench manufacturers. The only answer is proper training and continuous careful work. In addition, we do have better ways of turning wrenches with less danger. These include impact guns, torque multipliers, hydraulically operated wrenches, slugging wrenches, and pneumatic wrenches with precision torque control.

No one is paid to get hurt. In many occupations, people get hurt because of other people’s mistakes. Although users can be injured because somebody else damaged a wrench or over-tightened a fastener, even then, if taking proper precautions, the likelihood and severity of an injury is minimized.

With these steps users should be able to avoid wrenching problems and have wrenches last longer on the job. For further information on safety or to sign up for our safety program, visit https://www.wrighttool.com/safety.