May 21, 2024

How Strong is My Wrench

Tools are very carefully designed and inspected to be in accordance with the American Society of Mechanical Engineers (ASME) standards, which provide values for strength as well as dimensions. In practice, our designs pack as much strength as we can into the allowable space. This means that we are often substantially stronger than the value in the standard.

Clearance

The first thing to remember is that the strength of the wrench depends very much on the clearance between the wrench and the fastener. Both the fasteners and the wrenches have manufacturing tolerances. Wrenches and fasteners both wear from use and from corrosion increasing the clearance.

Hardness

The harder the fastener, the more torque it can take without damaging the fastener or the wrench. Outside of aerospace, very few fasteners have a Rockwell hardness over 32 Rc because more expensive material and more expensive manufacturing steps are required. This is not a problem except that the torque values given in the standards are based on the test mandrel with a hardness of 56 Rc. There is no simple factor converting these test values to lower hardness because the amount of change depends on the clearance and on the detail of the wrench profile.

Wrench profile: hex, double hex and other fasteners

For a hexagonal fastener, the strongest wrench has a six-point opening, which is about 10-percent stronger than a 12-point wrench. However, many mechanics prefer to use the 12-point wrench because it is slightly more convenient. The 12-point fasteners might seem to be twice as strong as six-point fasteners, but in practice, they are only about 50 percent stronger. The socket strength is limited by its diameter which has been designed for six-point fasteners; 12-point fasteners are usually used where there is no space for a larger diameter socket.

Installation and removal

When users ask about the strength of wrenches, they are usually thinking about choosing a wrench for installation on an assembly line where they want to avoid problems. However, if the product designer allows only enough space for the smallest wrench that will turn the fastener, there is likely to be problems in the field because the torque required to remove a fastener is usually equal to or up to double the torque that is applied to install the fastener.

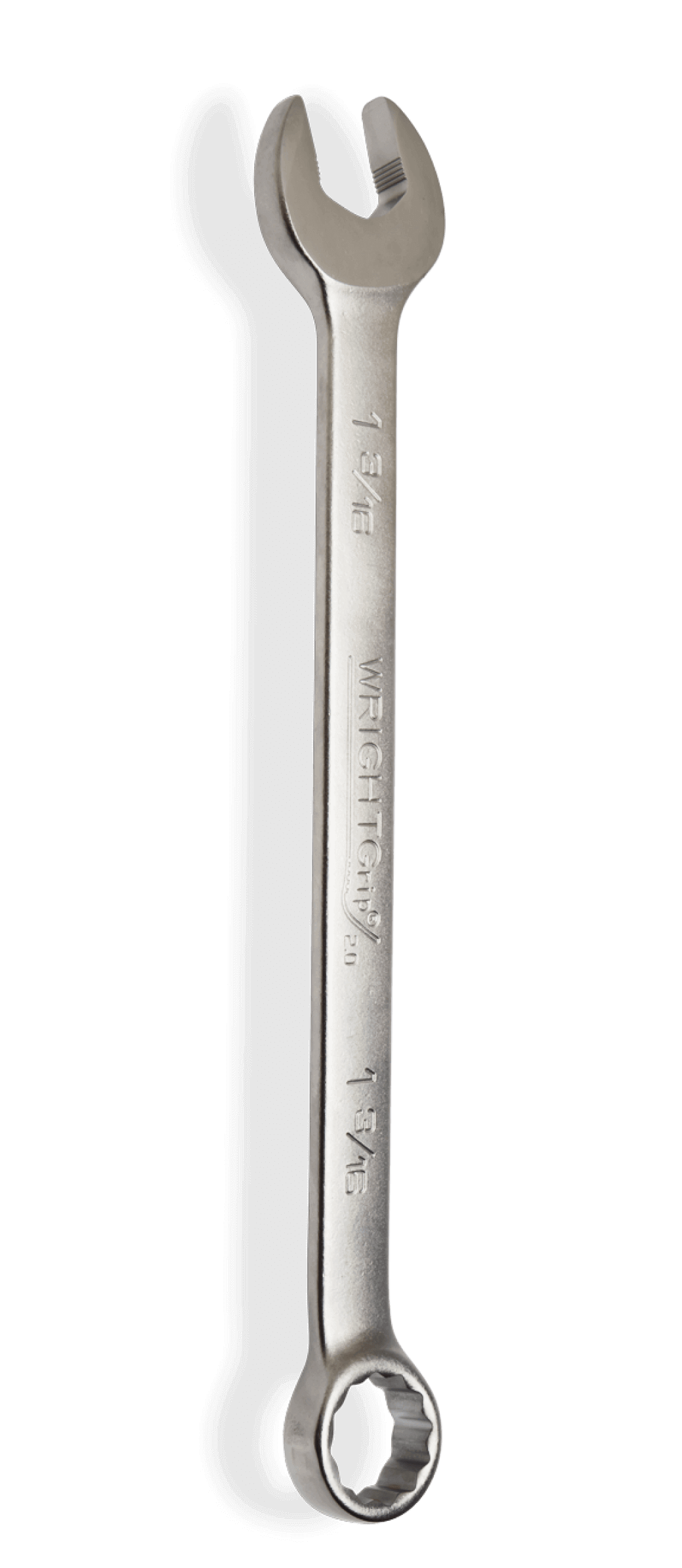

Sockets versus box wrenches versus open end wrenches

Sockets and box wrenches are of comparable strength, and both are substantially stronger than open-end wrenches, which should be used only for lighter loads or when it is not possible to use the box or socket wrench. One of the problems with open-end wrenches is that when they are overloaded, the jaws will spread permanently, and the wrench will be much weaker after that. However, there are open-end wrench designs that are more resistant to spreading and can safely be used for higher loads, but these designs are only available in premium wrenches.

Taking account of the above information will help to ensure users know when to use a wrench and how the design of the wrench helps its strength.