.png)

second to none

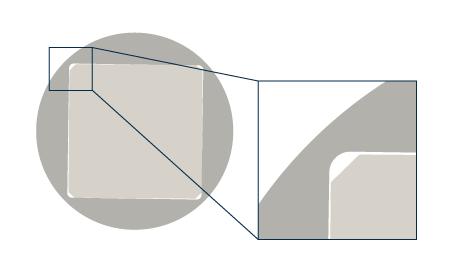

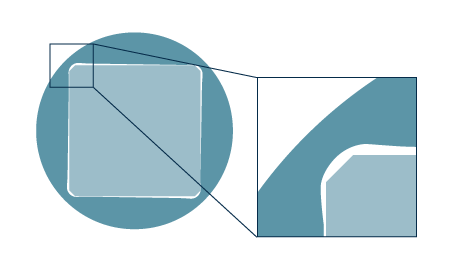

WRIGHTSQUARE™ USES PROVEN WRIGHTDRIVE 2.0® TECHNOLOGY ON THE SQUARE END OF THE SOCKET WHERE IT ATTACHES TO THE RATCHET OR IMPACT GUN.

That provides 10 times more contact area than conventional designs. By relocating load and stress away from the corners, it enhances performance and increases socket life.

Noticeable Performance

10X MORE CONTACT AREA ON DRIVE SQUARE

CONVENTIONAL DRIVE SQUARE

Load is too close to corners

Less contact area = more stress

More likely to fracture at corner

WRIGHTSQUARE™

Load/stress relocated away from corners

10X more contact than conventional

Corners have smallest cross-sectional area

Patented design: US 10442059 B2

WHY WRIGHTSQUARE™?

We’ve optimized the flat contact areas to remove force from the drive square corners.

We’ve added premium Wright alloy steel for increased strength, as well as ensured precision in our broaches give you the most consistent quality and tolerance levels achievable.

DON’T BELIEVE US? TEST IT OUT YOURSELF.

Even More Features

WRIGHTSQUARE™ IN ACTION

PRODUCTS WITH WRIGHTSQUARE™

.png)

3/4" Drive 12 Pt Deep Impact Sockets - SAE & Metric

Set 415 6 Pt. Standard SAE Impact Socket Set 13 PC

.png)

1-1/2" Drive 6 Pt Standard Impact Sockets - Metric

Set 407 6 Pt. Deep SAE Impact Socket Set 14 Pc

.png)

1" Drive 6 Pt Deep Impact Sockets - Metric

Set 408 6 Pt. Standard SAE Impact Socket Set 6 Pt

Set 467 6 Pt. Deep Metric Impact Socket Set 16 Pc

.png)

1" Drive 12 Pt Standard Impact Sockets - SAE

.png)

3/4" Drive 12 Pt Standard Hand Sockets - Metric

3/4" Drive Budd Wheel Impact Sockets - SAE & Metric

.png)

1-1/2" Drive 6 Pt Deep Impact Sockets - SAE

.jpeg)

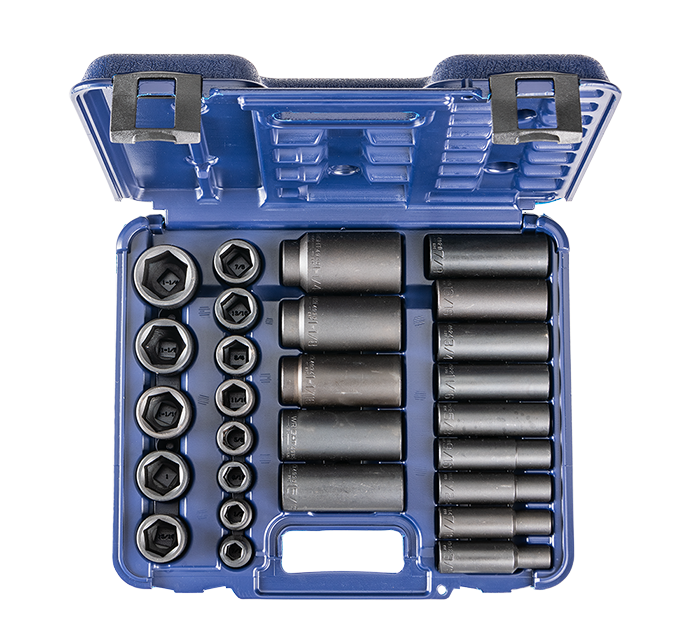

Set 423-MC 1/2" Dr 6 Pt Standard & Deep Blow Mold Socket Set 18 Pc

2-1/2" Drive Castellated/Spanner Sockets

Set 411 6 Pt. Standard SAE Impact Socket Set 11 Pc

3/4" Drive Ball Joint Impact Sockets - SAE

Set 412 6 Pt. Deep SAE Impact Socket Set 11 Pc

.png)

1-1/2" Drive 6 Pt Standard Impact Sockets - SAE

Set 40715-MC 6 Pt. Standard & Deep SAE Impact Socket Set 27 PC

.png)

1-1/2" Drive Castellated/Spanner Sockets

Set 466 6 Pt. Standard Metric Impact Socket Set 16 Pc

WRIGHT CLUB JOIN UP

join the club

wright club

Sign up to join the Wright Club and receive email notifications about exclusive offers and insights into what we’re up to.