March 20, 2023

Wrench Q&A Part One

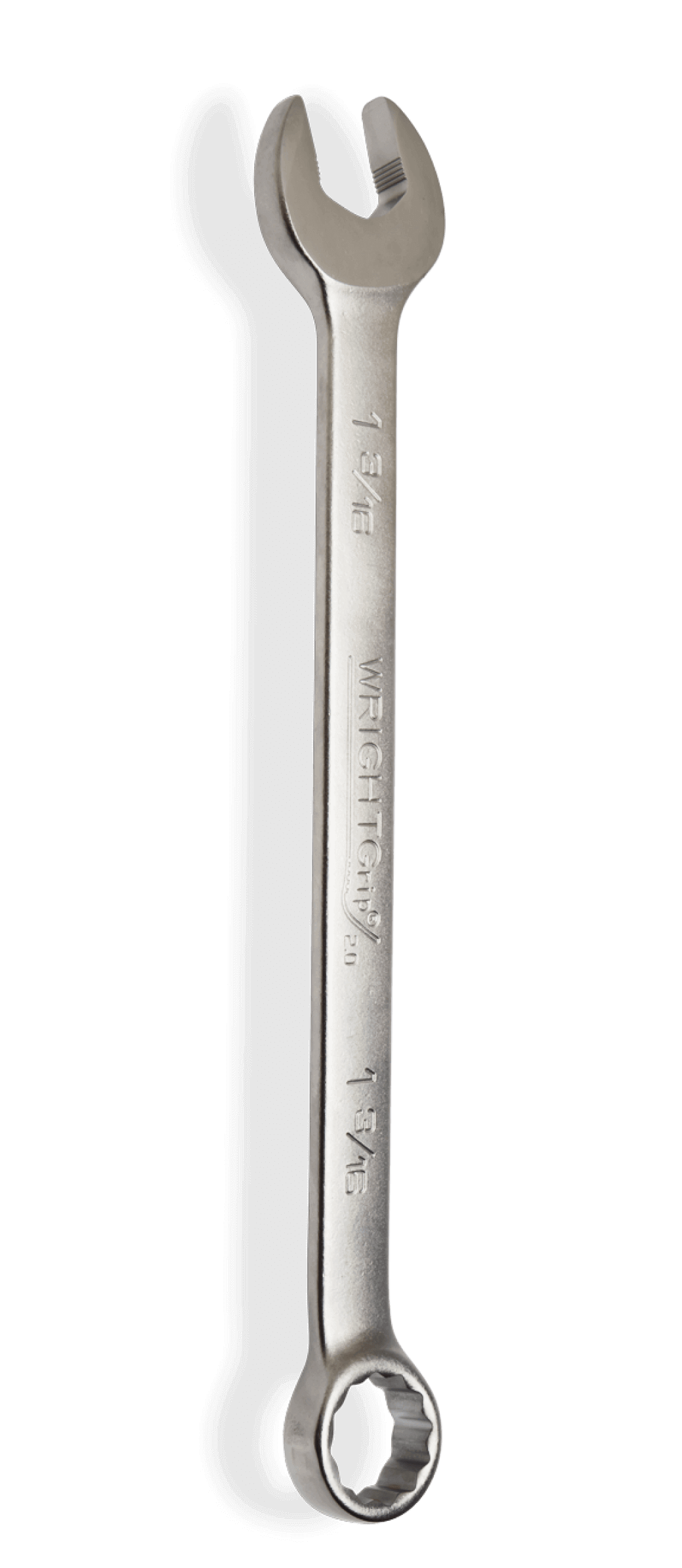

For almost 100 years, Wright has been forging tools and has a commitment to professional grade tools. With being experts in the field, we decided to answer some of the top questions our customers have when it comes to wrenches.

1. If you borrow your buddy’s wrench and it breaks, is this proof that you did something wrong?

Answer: No. The wrench may already have had a small crack as a result of being overloaded in the past. It’s possible the wrench was badly worn or deformed from heavy use. Wrenches that are badly worn are weaker than new wrenches. It’s always a good idea to carefully inspect a wrench before using it—even your own.

2. What is the difference between a shear bolt and a tension bolt? Why is this important?

Answer: A tension bolt is a bolt that is loaded in such a way that it tends to stretch the fastener. A shear bolt is loaded with the load perpendicular to the fastener. A shear bolt only needs to be tightened enough so it does not work loose, or it may be secured with a cotter pin. A tension bolt must be tightened to the correct amount, neither too much nor too little, or it is liable to break. Some joints have a combination of perpendicular and lengthwise loading. These should always be considered tension bolts and carefully tightened.

3. Is it better to over-tighten or under-tighten a bolted joint?

Answer: Both over-tightening and under-tightening of bolts is bad. Most bolts have additional load put on them after they have been put in use. If they have been over-tightened, this additional load may cause the bolt to break. If it has been under-tightened, the addition of a varying load may be enough to cause a slight gap in the joint assembly. At this point in time, there is no load on the bolt. The tension oscillates from no load to substantially higher than the tightening load. This high percentage of cyclic loading can cause a “fatigue” failure after a number of cycles, which can be as few as two or three or as much as a million. The answer to the question is that bolts should be tightened to the specified tension or torque, no more and no less.

4. If I can’t turn a bolt by hand, would it be better to use a cheater bar, a slugging wrench, or an impact gun?

Answer: An impact gun is the safest and best way of removing a very tight bolt. Not only is it much safer than a cheater bar, but the pulses produced by an impact gun are more effective than a steady pull. If an impact gun or power to run a gun is not available, a slugging wrench is a good choice. They are particularly useful for large fasteners.

5. When do you need to know the grade of a fastener?

Answer: There is no need to know the grade of a fastener to remove it. If you need to replace it, you should replace it with a fastener of the same or higher grade. If you are installing it, it is best to have an engineered recommendation. If that is not available, you can look into a handbook for a recommendation. To do this, you need to know the grade of the bolt to avoid either under-tightening or over-tightening.

6. Is a worn wrench as strong as a new wrench?

Answer: A worn wrench is never as strong as a new wrench. A worn wrench on a worn fastener is even more likely to break. Also, a worn wrench is more likely to damage the corners of a fastener. When this happens, it may not be possible to remove the fastener with a brand new wrench.

7. What fasteners should never be reused?

Answer: Fasteners in high-strength applications should never be reused even if they look to be in good shape. Fasteners not only get worn but accumulate internal microscopic damage as a result of cyclic fatigue. Therefore, fasteners used in transportation which could cause loss of life in their failure should never be reused.

When using a wrench there’s a million questions that can pop up but with this guide, Wright can help!

To check out our full line of wrenches visit, https://www.wrighttool.com/products/wrenches