August 1, 2025

Everything You Need to Know About Black Oxide

Today, we’re breaking down what black oxide really is, how and why Wright uses it, and what you need to know to properly maintain it. Whether you’re working in heavy industry or just want your tools to last, understanding black oxide is key to keeping performance high and corrosion low. Let’s get started.

- What is Black Oxide?

Black oxide is a chemical conversion process used to blacken the surface of a part without adding a thick coating. A chemical conversion process uses a chemical solution to force a reaction on the surface of the part rather than a plating or coating process, which adds a thicker layer on top of the base material. Black oxide is most commonly done for ferrous metals (metals containing iron), but there are ways to black oxide other metals, such as copper and stainless steel, which are designed specifically to resist surface reactions. The appearance of the finish is usually black or a dark bluish black. It can be glossy or matte, usually depending on the finish of the part before the process and the post-conversion treatment applied after blackening.

- When and Where Does Wright Use Black Oxide?

Wright utilizes black oxide on tools marked as “industrial finish” and ALL impact sockets and attachments. As mentioned above, black oxide is not a coating, but a conversion of the surface of the tool, therefore, it presents zero risks of anything peeling, chipping, flaking, etc. from the tool. This becomes critical in sensitive industrial environments where even the smallest particle of chipped coating could pose a risk to the operation of equipment, the environment, or human health. Due to the intended use of impact sockets, acute concentrated impacts are not favorable for many coatings and present a risk of separating from the substrate with repetitive impacts. This is why black oxide is a leading industry choice for these applications.

- How Does Black Oxide Need To Be Maintained?

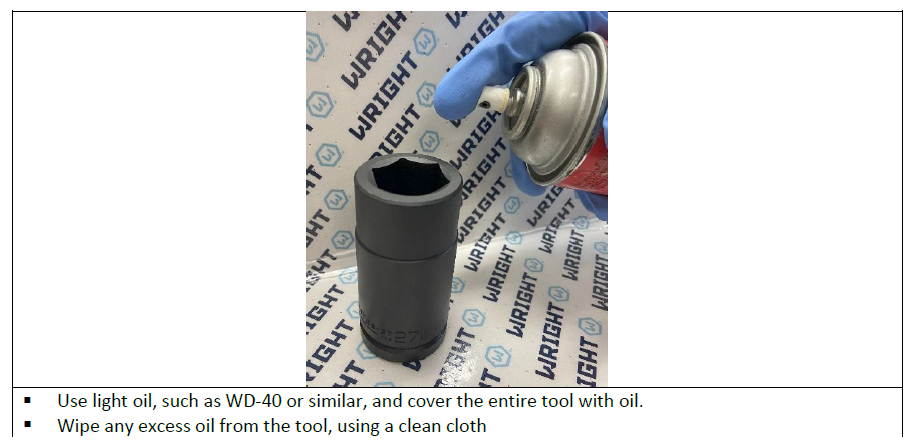

It’s a common misconception that black oxide parts are corrosion resistant. In reality, a part that has ONLY been blackened by the process isn’t much more resistant to rusting than a bare steel part. To provide an increased level of protection, black oxide parts are coated in oil, wax or sometimes a lacquer finish. For this reason, black oxide finishes require additional care and maintenance when used in environments where corrosion is a concern or when stored for prolonged periods of time. Parts should be inspected routinely and after use for signs of corrosion beginning to form. Wright uses an oil-based rust preventative coating over black oxide finishes. Over extended periods of time, this oil can begin to evaporate, leaving the tool more vulnerable to corrosion. Tools should be re-oiled periodically to preserve the longevity of the black oxide.

At Wright, it plays a crucial role in the performance of our impact sockets. But remember, like any surface, black oxide needs the right care to deliver long-lasting protection. Re-oiling and routine maintenance are simple steps that make a big difference. Black oxide offers more than just a sleek, dark finish, it’s a practical, reliable solution for industrial tools.

See the following page for how to identify when a black oxide finished tool may need re-oiled and the process for re-oiling.