Second to none

Our all-American blow molded cases are engineered to withstand the harshest environments.

Of the many choices you have, choose between options built to outlast the competition. The durability of our blow molded cases is second to none and no other material even comes close when it comes to impact strength.

Tough jobs need tougher protection.

Updgraded performance

STRENGTH & PRODUCT PROTECTION.

Because integrally molded interiors are part of the case structure itself and not glued or snapped in later, the overall case is stronger and more shock absorbent. The air space between the double walls prevents shocks to the case exterior from being transferred to the case interior – providing superior case protection.

built to outlast

Economy & Utility.

The exterior and the interior of a double-wall blow molded case are molded as a single piece. That means that an interior designed specifically to package your product is integral to the overall structure of the case – not a separate insert that is made separately and installed later. The air spaces between the double walls are extremely useful. In the top or “lid” of a case, that air space is often used to store product manuals, forms/checklists, and marketing materials. In the bottom or “base” of a case that air space is an ideal place to store ancillary items – things like cables and hoses to hold them securely in place.

All-American Protection.

Take a look at our blow molded casing options

.png)

Blow Molded Case for Set 40715-MC

Set 461 6 Pt. Deep Metric Impact Socket Set 12 Pc

Set 412 6 Pt. Deep SAE Impact Socket Set 11 Pc

Set 339-MC Dr 6 Pt Standard & Deep SAE Blow Mold Socket Set 31 Pc

Set 223-MC 6 Pt. SAE Standard & Deep Blow Mold Socket Set 25 Pc

Set 466 6 Pt. Standard Metric Impact Socket Set 16 Pc

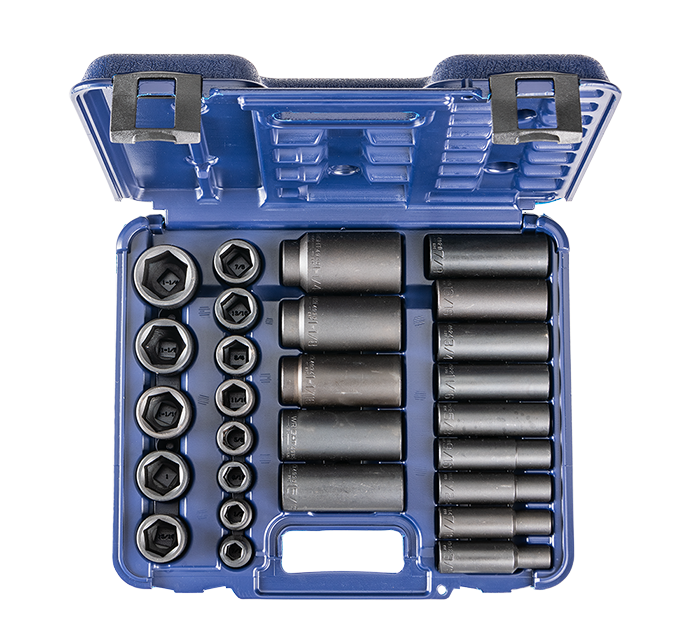

Set 40767-MC 6 Pt. Deep SAE & Metric Impact Socket Set 30 Pc

Set 415 6 Pt. Standard SAE Impact Socket Set 13 PC

Set 610-MC 3/4" Dr 6 Pt Standard Impact Blow Mold Socket Set 14 Pc

.png)

Blow Molded Case for Set 40767-MC

.jpeg)

Set 423-MC 1/2" Dr 6 Pt Standard & Deep Blow Mold Socket Set 18 Pc

Set 411 6 Pt. Standard SAE Impact Socket Set 11 Pc

Blow Molded Case for Set 423

Set 460 6 Pt. Standard Metric Impact Socket Set 12 Pc

Set 467 6 Pt. Deep Metric Impact Socket Set 16 Pc

Set 408 6 Pt. Standard SAE Impact Socket Set 6 Pt

Set 407 6 Pt. Deep SAE Impact Socket Set 14 Pc

Blow Molded case for Set 46667-MC

Set 40715-MC 6 Pt. Standard & Deep SAE Impact Socket Set 27 PC

Set 46667-MC 6 Pt. Standard & Deep Metric Impact Socket Set 32 Pc

WRIGHT CLUB JOIN UP

join the club

wright club

Sign up to join the Wright Club and receive email notifications about exclusive offers and insights into what we’re up to.