May 3, 2023

Wrench Q&A Part Two

In this two-part series we answer some of the top questions our customers have when it comes to wrenches.

1.What problems do 12 pt. fasteners present?

Answer: Most 12-pt. fasteners are used in aerospace where it is always important that the fastener does not fail. Twelve-point fasteners are always designed to have smaller heads than normal, which means they require a higher load on the wrench than 6-pt. fastener would impose on a wrench. At the same time, they are higher strength at least 180,000 psi and sometimes higher. This requires the best rate of wrenches in good condition. Wright Tool makes spline wrenches which have been designed to turn both 12 pt. and spline fasteners.

2. Why don’t fastener manufacturers put a suggested torque value on their packaging?

Answer: The correct torque or fastener depends on factors beyond the manufacturer’s control. Is it going to be used on a shear joint or a tension joint? Are the threads it engages with well formed? Is the joint lubricated at the time of assembly? If a torque wrench is used, is the torque wrench in calibration

3. What’s the best wrench for a tubing fitting?

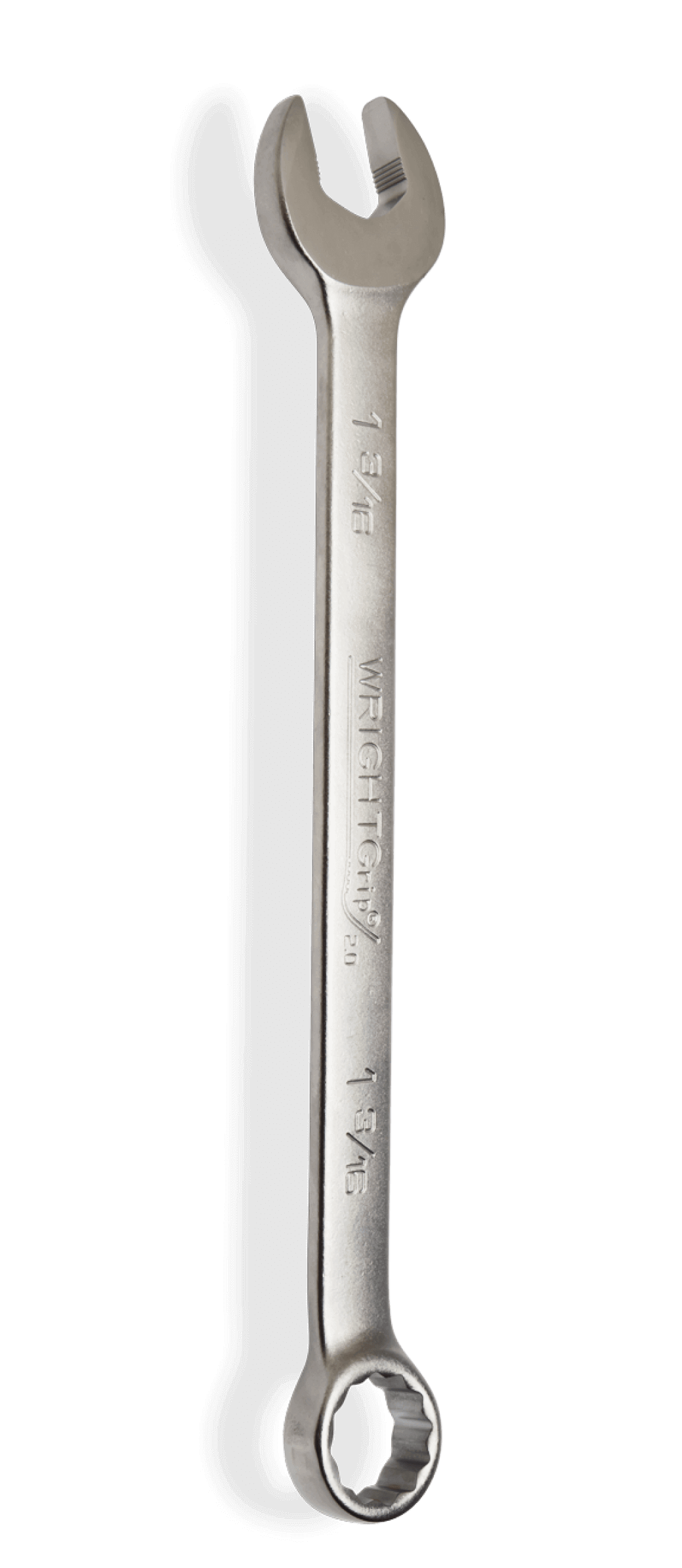

Answer: An open-end type of wrench is normally required. There are special Flare Nut wrenches with a narrow gap, so it makes contact with six sides of the fastener. These reduce the chance of squeezing a fastener which may cause leakage. Ordinary open-end wrenches should not be used because they make contact on two corners and tend to deform the fastener. However, special designs of open-end wrenches such as the Wright Grip 2.0 has more steel-to-fastener contact in high-stress areas to stiffen the jaws, increase tool strength and reduce permanent jaw spread

4. Is penetrating oil worth using?

Answer: Penetrating oil is always a help in loosening fasteners. There are some situations where oil is not permitted.

5. Why don’t wrench manufacturers put a suggested maximum torque for their wrenches?

Answer: The maximum torque that a wrench will transmit to a fastener without breakage or damage to the fastener depends not only on the wrench but also on the fastener’s wrenching areas. Are they under size or rounded or rusty, oiled or dry?

6. Does it make any difference what sequence you tighten lug bolts in Canada?

Answer: Yes. If you do it the wrong way, you are in violation of the law. For any joint with multiple fasteners, it’s important that the fasteners be equally tight. This can occur only if tightened in the proper pattern because increasing the load on one fastener can reduce the load on another fastener. If the fasteners are unequally loaded, the fastener with the extra load may fail putting an additional load on the remaining fasteners. Then the most heavily loaded of the remaining fasteners will break putting higher load on the remaining fasteners, and so forth until they are all broken, or disaster occurs first.

7. Is a box wrench or an open-end wrench fastener stronger?

Answer: On combination wrenches, the open end is usually about a third of the strength of the box end, and, therefore, should not be used for high torque. Not only can the wrench break, but the fastener is more likely to be damaged.

As professionals, we know you may have questions as you’re in the field and with this guide we can help.

To check out our full line of wrenches visit, https://www.wrighttool.com/products/wrenches