December 12, 2022

Spotting Worn Sockets

Sockets can wear and crack as they are used and should always be inspected before use. When searching for damage, look for cracks, bends and signs of excessive wear. If used improperly, it can result in injuries and have the potential to break. That’s why it’s important to spot worn sockets before damage is caused. In this blog, we will cover different ways to spot worn sockets and the damage they can cause.

Recognize the Warning Signs of Wear

Worn sockets will have noticeable wear and tear, which will show obvious signs to the operator. From this, the user might see predictable behaviors like slipping, mushrooming or weak engagement.

No matter how good a socket is, the fit on the fastener becomes worse as the socket wears. Therefore, sockets should be removed from service when they become worn. This is particularly important when working with high-strength or 12-point fasteners. Look for wear in the nut end, and if the difference is apparent, it should not be used.

Does It Feel Sloppy?

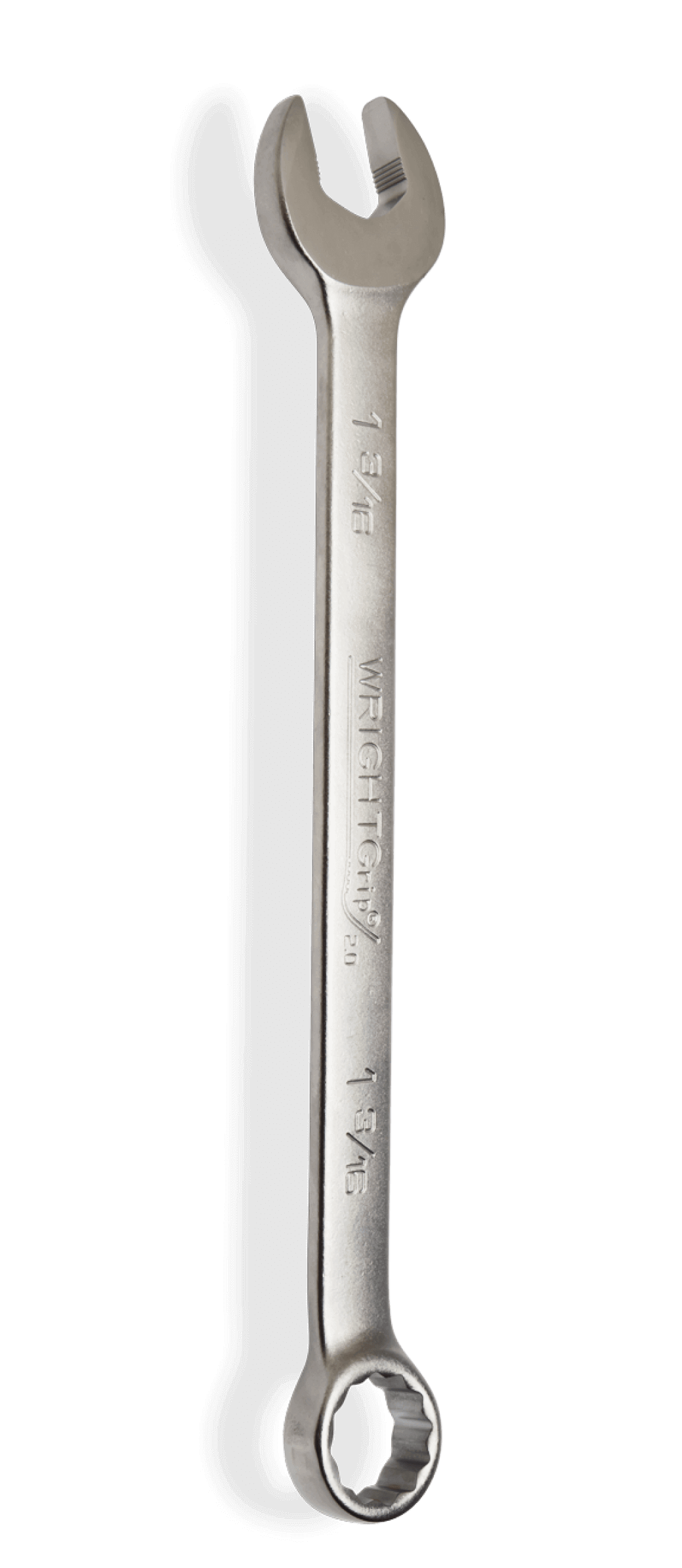

Another clue that a wrench is worn is when it feels sloppy on a fastener. Likewise, if the drive square is sloppy or shows signs of mushrooming around the square, the socket should be replaced. Worn sockets are not only weaker and less likely to do the required job, but they are also more likely to round the corners of fasteners.

Using Sockets on Worn Fasteners

The same points regarding the opening of the socket also apply to the fastener. If the fastener head is worn or rusted, it will not allow good engagement. Normally, the operator does not have a choice. One precaution, however, is not to reuse fasteners with damaged heads and to recognize and take extra care in turning fasteners with rounded or rusted heads.

The use of 6-point sockets is often appropriate since they work better on worn fasteners than 12-point sockets. Impact sockets are stronger than hand sockets and can be used in place of hand sockets for tough jobs.

Visible Wear and Tear

Visible damage is a clear sign that your sockets will need to be replaced. Wear and tear can vary from chipping, rust and discoloration and dullness. Damage can happen to sockets due to repeated use, misuse, exposure to elements and time.

How to Make Your Tools Last Longer

Users can make their tools last longer with the proper care and procedures. Always inspect your tools first before using them. Routine tool inspections can help identify signs of wear and tear before it worsens to the point that you must replace or repair your tools.

How you store your tools is also important as the environment can make wear and tear happen a lot faster. To protect tools from dust and the elements, consider storing them in a toolbox, tool chest or cabinet.

With these tips, you should be able to recognize worn sockets and know the damage they can cause. Never use a socket that is damaged, broken or badly corroded. Remember, before working on any job, always make sure to check your sockets. Also, discard any tools after normal service life and replace the tool.

For more information on safety and to sign up for our safety program, visit https://www.wrighttool.com/safety.